Todos los cursos

Mira cómo Marriott utilizó las 4 disciplinas de la ejecución para enfocarse en y ejecutar sus metas más importantes, mientras aumentaba su nivel de compromiso. Para obtener más información, visita: http://www.franklincovey.com/execution/. Conéctate con Franklin Covey en Twitter: https://twitter.com/franklincovey. Conéctate con Franklin Covey en LinkedIn: https://www.linkedin.com/company/franklincovey. Franklin Covey es una empresa global especializada en la mejora del rendimiento. Ayudan a las organizaciones a lograr resultados que requieren un cambio en el comportamiento humano.

La primera disciplina te anima a elegir un objetivo importante, conocido como tu WIG (Wildly Important Goal, o Meta Extremadamente Importante). Puedes elegir dos objetivos, pero se recomienda elegir solo uno. Aunque puede ser difícil escoger solo una meta, es necesario para eventualmente vencer el torbellino. Los líderes tienden a querer agregar más metas a la lista, pero esto es contraproducente porque el enfoque es clave para lograr el éxito. Los seres humanos están genéticamente predispuestos a hacer una cosa con excelencia. Junto con tu equipo y tu gerente, elegirás un WIG y te enfocarás en ejecutarlo. Para elegir un WIG, primero haz una lluvia de ideas con todas las posibles metas que tu equipo necesita completar. El WIG tiende a ser más efectivo y exitoso cuando se recopilan más posibilidades creativas. Tu WIG debe ser lo más importante que tu equipo considere que tendrá el mayor impacto en el éxito. Asegúrate de que el WIG que elijas sea un objetivo desafiante pero alcanzable. Una vez que logres este objetivo, puedes incorporarlo a tus tareas diarias y comenzar a perseguir otro.

La tercera disciplina consiste en asegurarse de que todos conozcan sus puntajes en todo momento, para que puedan saber si están ganando o no. Las personas rinden mejor cuando están llevando la cuenta de su progreso. ¡A todos les gusta la competencia! Como resultado, esta disciplina gira en torno a la idea de involucrar a los miembros de tu equipo para que den lo mejor de sí mismos. Se fomenta que los miembros del equipo se sientan emocionalmente motivados para ganar.

Palabras clave: Documento informativo, visión de la empresa, visión, historia de la empresa, historia, estructura de la empresa, tipos de piedra, piedra, cronograma de reuniones, títulos de trabajo, Lucid, credenciales, reunión trimestral.

American Stone, Retail stone sales, Manufacturing stone products, Stone maintenance, Corporate support services, Stone yardhands, Stone cashiers, Stone salespeople, Stone drivers, Inbound sales, Outbound sales, Sales pros, Utah stone locations, Vancouver Washington stone store, Idaho mechanic shop, Stone splitters, Stone production crew, Stone quarry operators, Oakley Idaho saw shop, Salt Lake saw shop, Quarry management, Stone production Salt Lake, Stone production Oakley, Human resources in stone industry, Accounting in stone business, Stone industry executives, Marketing for stone products, Retail career advancement, Manufacturing career advancement, Maintenance career advancement, Corporate office career growth, Stone yardhand to driver, Stone mechanic career, Saw shop positions, Stone splitter to operator, Quarry foreman roles, Tuition reimbursement benefit, Leadership training in stone business, Quarry management roles, Corporate office roles, Accounting clerk advancement, Intermediate accountant roles, Chief financial officer stone company, Human resources growth, Stone company managers, Dan Thomas president, Roger Boyd vice president, Johnny Prieto mechanic lead, Eric Ward production manager, Ismael Martinez PSL shift lead, Blas Ocampo PSL second shift, Fernando Rodriguez Oakley manager, Rex Larsen quarry manager, Alberto Castañeda assistant quarry manager, Toby Winchester GM Salt Lake, Jeff Moore GM Sunset, Michael Harhi GM Heber City, Jason Jeffs GM Vancouver, Cynthia VanBibber HR manager, Bev Thomas CFO, Jerry Thun controller, Alex Johnson accountant, Clarissa Thomas corporate admin, Russ Fellows marketing head, org chart, organization organizational chart.

El reembolso por kilometraje es diferente al reembolso por gastos prepagos. Registra los kilómetros, el destino, adjunta el formulario de kilometraje y envíalo.

Esto te muestra cómo crear, organizar y utilizar proyectos y tareas para el trabajo.

Palabras clave: Seguro de salud Allstate, elegibilidad para seguro de salud, planes de salud con deducible alto (HDHP), HSA, contribuciones a la Cuenta de Ahorros para la Salud, inscripción en seguro de salud para empleados, opciones de seguro dental y de visión, comparación entre Plan 3 y Plan 4 de Allstate, detalles de cobertura de seguro de salud, atención preventiva cubierta al 100%, eventos calificativos para seguro de salud, beneficios fiscales de salud, porcentajes de coaseguro, máximos de gasto de bolsillo para seguro de salud, porcentajes de coaseguro, seguro patrocinado por el empleador, cobertura inmediata de seguro dental, seguro de visión combinado con dental, deducción fiscal de gastos médicos, período de inscripción abierta para seguro de salud, información sobre la continuación de cobertura COBRA, actualizaciones de precios de seguro de salud grupal, primas, médicos preferidos por PPA.

Palabras clave: Elegibilidad, fechas de inscripción, jubilación 401(k), contribuciones del empleador, retiro anticipado, excepciones por dificultades, formulario de transferencia, inicio de sesión en Future Plan, préstamo.

Revisa la guía del producto en los enlaces externos al final de esta página y responde preguntas sobre lo que has aprendido.

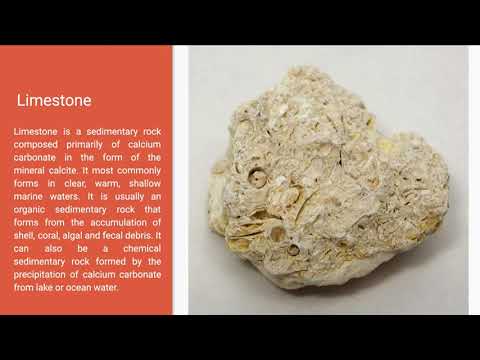

El revestimiento de piedra delgada es piedra natural pura cortada en láminas finas para hacer superficies hermosas y únicas. El revestimiento de piedra delgada mantiene la belleza natural y la textura de la piedra tal como estaba cuando salió de la tierra. Recortamos el lado posterior de la piedra, creando una tira delgada para una instalación fácil y uniforme. En pocas palabras, es una piedra de construcción más delgada alineada en una variedad de patrones para lograr una amplia gama de estilos. Consulta los enlaces externos para más detalles. Alpine es un estilo de mosaico, Castlerock está diseñado para constructores, Promontory se caracteriza por tener un borde aserrado, Sawtooth es de estilo ledge natural, y Wasatch utiliza patrones cuadrados y rectangulares.

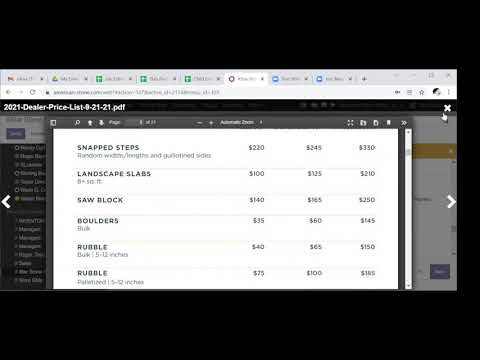

American Stone vende una variedad de escalones, que incluyen los siguientes tipos: Storm Mountain 6-8" Rectangular Steps, Buckskin 3-5" Steps, Buckskin 5-8" Steps, Storm Mountain 4-6" Rectangular Steps, Storm Mountain 6"-8" Natural Steps, Cherokee Snapped Steps, Autumn Gold 4-6" Steps, Autumn Gold 5-8" Steps, Storm Mountain 4-6" Natural Steps, y Cherokee 3-5" Steps. Los tamaños estándar para escalones son 3x4 pulgadas, 4x6 pulgadas y 6x8 pulgadas, y también pueden producir escalones en tamaños más grandes, de 8 pulgadas o más. Las losas generalmente se crean a partir de piedra plana, como la pizarra, que es adecuada para losas delgadas. Las losas también son útiles como "material de corte". Existen diferentes tipos de losas que vende American Stone, entre ellos: Buckskin 8"+ Slabs, Cherokee 8-18" Slabs, Storm Mountain 8-18" Slabs, Windridge 4-8" Slabs, Windridge 8-18" Slabs, Cherokee Fire Slab, Autumn Gold 3-5" Landscape Slabs, Autumn Gold 5-8" Landscape Slabs, Autumn Gold 8"+ Landscape Slabs, y Chestnut 2-3" Slabs. Para más detalles, puedes consultar la matriz de productos de losas en el siguiente enlace externo: https://docs.google.com/spreadsheets/d/1VPcbkgFALYRT7TUhoqrPrgf90udFe9Bon2h8EGMatHc/edit?usp=sharing Slab Product Matrix

Objetivo: Introducción a la Systemology y el Sistema CCF Systemology es un curso que enseña cómo identificar y mejorar los sistemas dentro de un negocio. Un sistema es una serie de pasos que, cuando se siguen, producen un resultado predecible. Algunos ejemplos de sistemas son una rutina matutina, hacer ejercicio y comer. En este curso, aprenderás a identificar los sistemas en tu lugar de trabajo, encontrar las áreas donde no están funcionando bien y hacer mejoras para que los sistemas sean más eficientes y efectivos. El objetivo de Systemology es crear un negocio donde todos los sistemas trabajen juntos para producir los mejores resultados posibles para la empresa y sus empleados.

How To: Maintain the Marketing File Structure for a Monthly Marketing Campaign